Innovative Hazelnut Harvesting Equipment to Boost Farm Productivity

Introduction

Hazelnut farming presents unique challenges, especially when it comes to efficiently harvesting and processing the nuts. The right equipment can significantly enhance productivity, reduce labor costs, and ensure that the harvest is collected quickly and with minimal waste. Wurdinger Manufacturing offers a range of innovative hazelnut harvesting equipment that helps farmers maximize their harvest season. In this article, we will explore the advanced features of Wurdinger’s hazelnut harvesting solutions and how they can boost farm productivity.

1. Streamlined Harvesting with Advanced Machinery

The process of hazelnut harvesting can be labor-intensive and time-consuming without the proper tools. Traditional methods often require multiple passes through the orchard, which can lead to delays and increased costs. Wurdinger Manufacturing has developed hazelnut harvesting equipment that streamlines this process, allowing farmers to collect nuts efficiently in a single pass.

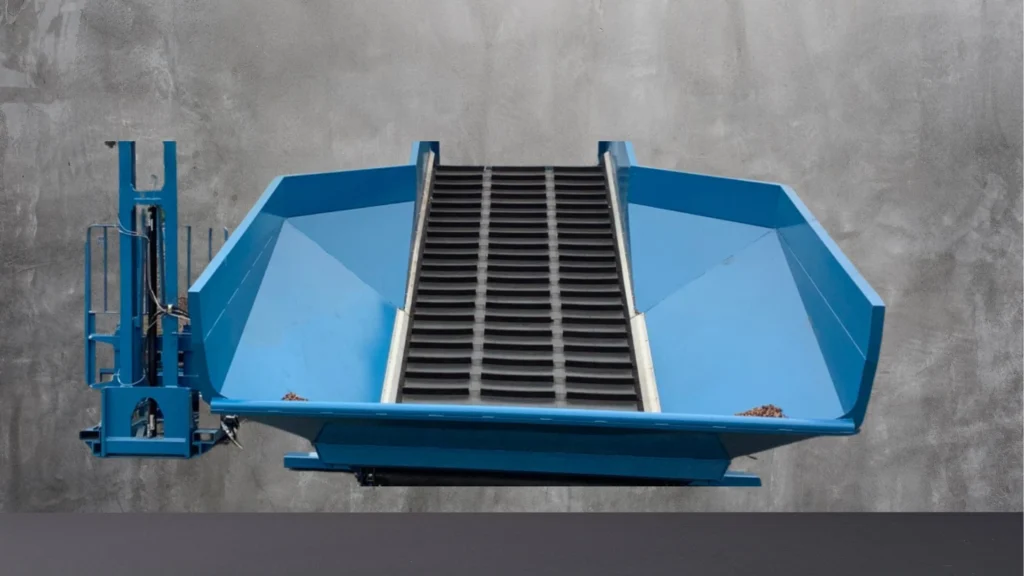

Their innovative machinery is designed to pick up hazelnuts quickly and effectively from the orchard floor, reducing the time spent on manual labor. With automated collection systems, Wurdinger’s equipment eliminates the need for extensive manpower, making it easier to cover large areas of the orchard in a shorter amount of time.

2. Durability for Tough Conditions

Hazelnut orchards often present challenging terrain, including uneven ground and debris. To withstand these conditions, Wurdinger’s hazelnut harvesting equipment is built with durability in mind. Made from high-quality materials, these machines are designed to operate in rough environments without suffering damage or frequent breakdowns.

Farmers can rely on Wurdinger’s equipment to keep performing season after season, minimizing downtime and reducing repair costs. This durability ensures that hazelnut farmers can maximize their harvest window without interruptions, leading to increased productivity and better returns on investment.

3. Increased Harvest Efficiency and Reduced Waste

A key benefit of using Wurdinger’s hazelnut harvesting equipment is the efficiency it brings to the harvesting process. The machinery is designed to reduce nut loss by minimizing the amount of waste during collection. With precise harvesting technology, nuts are collected cleanly from the orchard floor, ensuring that fewer nuts are left behind.

This increased efficiency not only boosts overall yield but also ensures that farmers can meet market demands more effectively. By capturing a higher percentage of the harvest, farmers see an improvement in profitability and can make the most of every season.

4. Customizable Equipment for Specific Orchard Needs

No two hazelnut orchards are the same, which is why Wurdinger Manufacturing offers customizable equipment that can be tailored to the specific needs of each farm. Whether dealing with varying orchard sizes, tree spacings, or terrain challenges, Wurdinger’s harvesting machinery can be adjusted to optimize performance.

Farmers can choose equipment that best suits their operational scale, from smaller, more compact machines for tight rows to larger, high-capacity harvesters for extensive orchards. This flexibility ensures that each farm can get the most out of their equipment, improving both efficiency and productivity.

5. Integration with Processing Equipment

In addition to harvesting, the post-harvest process plays a critical role in the overall efficiency of hazelnut farming. Wurdinger Manufacturing provides equipment that integrates seamlessly with processing systems, such as nut carts and cleaning trommels, ensuring a smooth transition from the orchard to processing.

This integrated approach reduces the amount of time and labor needed to move harvested nuts to the processing stage. By streamlining both the harvesting and processing workflows, Wurdinger’s solutions contribute to greater operational efficiency across the entire production cycle.

6. Cost Savings Through Automation

One of the most significant advantages of Wurdinger’s hazelnut harvesting equipment is its ability to reduce labor costs through automation. Traditional hazelnut harvesting methods often require a large labor force to collect and transport nuts, leading to higher operational expenses.

Wurdinger’s automated solutions allow for fewer workers to manage the same, if not larger, harvest volumes. The efficiency of these machines means that farmers can cover more ground in less time, reducing the need for seasonal labor and cutting overall costs. Over time, these cost savings add up, making Wurdinger’s harvesting equipment a sound investment for hazelnut farmers.

Conclusion

For hazelnut farmers looking to improve their harvesting efficiency and boost farm productivity, Wurdinger Manufacturing’s hazelnut harvesting equipment offers the perfect solution. With its focus on durability, efficiency, and automation, Wurdinger’s equipment streamlines the entire harvesting process, ensuring that farmers can maximize their yields while reducing labor costs. By investing in these innovative tools, hazelnut farmers can meet the growing demand for high-quality nuts with ease.

To learn more about hazelnut harvesting equipment or explore other agricultural tools from Wurdinger, visit our Hazelnut Processing section or contact Wurdinger Manufacturing for more information.

Internal Links:

- Discover more about Wurdinger Manufacturing

- View our full range of Hazelnut Processing Equipment

- Contact us via our Contact Page for inquiries about hazelnut harvesting equipment.

- wurdinger Manufacturing Social Media